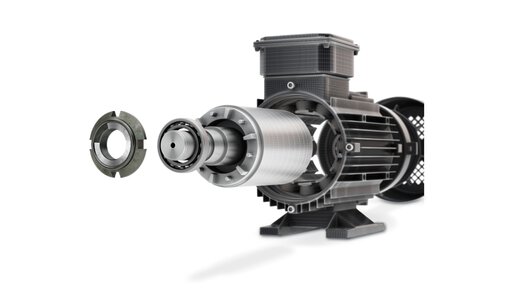

The shaft lock nut offers optimal safety when fastening bearings for thread tolerance ISO6H.

Dimension spectrum

- M8 to M100, material steel SS400

- M10 to M150, material steel S45C

- M10 to M100, material stainless steel SUS304 (A2)

Screw locking

For permanent joints

Bearings and gears fastened on shafts can loosen or come off under dynamic loads. The innovative FINE U-NUT® prevents this through sophisticated engineering: The nut locking function is integrated directly in the nut. This means that an additional locking element is unnecessary and machine operation becomes more efficient.

Plus Factors

The friction lock on the thread of the grooved nut effectively prevents the connection from loosening.

The FINE U-NUT® can be mounted easily and cost-effectively with hook or socket spanners using standard tools - even when maintenance is required. Furthermore, no additional securing element is necessary.

The FINE U-NUT® holds longer – fewer error sources at installation and high nut quality pay off.

FINE U-NUT® shaft nuts are suitable for high-speed rotation and alternating direction of rotation.

No need for an additional locking element, no need to mill a keyway. Storage costs and work time are reduced, since you only have one element to keep in stock.

The FINE U-NUT® improves the rotational properties of the shaft. It also can be used on thin-walled shafts.

Method and principle

FINE U‑NUT® shaft nuts are used to fasten bearings and other machine parts on shafts. They are classified as mechanical installation methods and offer the advantage of easy bearing replacement. For instance, complex shaft preparation is unnecessary for servicing.

Rotating shafts can cause shaft nuts to loosen. Consequently, shaft nuts must be used with a nut locking element to ensure that the application is safe and reliable.

This is where the FINE U-NUT® advantages come in: The FINE U-NUT® incorporates a flexible metal ring that presses against the thread as the nut is screwed on. The metal ring produces a controlled friction lock on the thread. The friction lock is strong enough to prevent the connection from coming loose at constant tightening torques.

The FINE U‑NUT® was developed to reduce overall costs when installing bearings and improve the quality of the connection.

The FINE U‑NUT® integrates the nut locking function directly in the shaft nut. A 270° lockring made of high-grade A2 stainless steel is built into the nut. This lockring exerts spring force on the thread flanks during and after installation and generates a clamping force between the nut and the thread. The resulting friction torque is greater than the loosening torque that occurs in the application. The friction lock effectively secures the machine part against loosening. It effectively prevents the machine part from loosening or coming off even at high rotational speeds and alternating direction of rotation.

The standard version of the FINE U-NUT® is the optimal solution for many applications. The nut is available in Böllhoff's standard range.

The second type, the TWIN FINE U‑NUT® has two lockrings inserted. This increases the clamping force on the thread. In addition, the TWIN FINE U‑NUT® is designed for higher thread tolerance accuracy (ISO4H). This means greater precision for the contact surface, which makes it easier to produce the thread and bearing surface.

Usually conventional shaft nuts must be secured to the shaft with an additional locking element. This additional locking element must prevent the nut from coming loose, particularly at high rotational speeds. Yet at the same time this locking element must not compromise the accuracy of the threaded joint or its transmission of the forces that occur. Design and installation with an additional locking element are more complex and introduce an additional source of error.

Locknuts only provide temporary locking. Circlip constructions and tooth lock washers with locking tabs and keyway, or bow shackles and securing plates are laborious to install and often fail to provide adequate axial fixation. If service is required, time-consuming dismantling may be necessary.

The FINE U NUT® eliminates the need for additional locking elements and the associated costly lathing and milling tasks required to create a keyway on the shaft. In addition, no extra time-consuming design or installation tasks are required.

The FINE U‑NUT® can be quickly installed with a C-spanner. The shaft must have bolt thread as specified in ISO 965, with a thread tolerance of ISO6g (JIS6g). The thread end should be bevelled so the nut can easily be screwed on. Use lubricating oil, particularly for shaft materials with low hardness.

After installing the machine parts, screw the FINE U‑NUT® onto the shaft with the lockring facing outwards. The end of the bolt must protrude at least two thread turns.

The FINE U‑NUT® must not be used on shafts where a keyway has already been produced, as this would reduce the clamping force and risk damaging the lockring.

If service is required the FINE U‑NUT® can be reused multiple times with negligible loss of clamping force.

Information and more

Are you interested in FINE U-NUT® shaft nuts? Please download further information here.