Success stories

Tôlerie Forézienne

Our customised solution for productivity gains.

Subsidiary of the Poujoulat group, European leader in chimney flue systems.

Tôlerie Forézienne specializes in chimney manufacturing and maintenance, fine sheet metal work subcontracting and urban design furniture.

Initial situation

Chimney flues

Tôlerie Forézienne produces its chimney flues out of a perfect mastery of sheet metal work and employees use state-of-the-art machines.

We step in to take charge of projects from design to delivery, Tôlerie Forézienne pulls out all the stops to achieve the final result the customer wants. To meet this challenge day in, day out, this subsidiary chose to increase productivity regarding crimping and clinching joints.

Tôlerie Forézienne has two separate workstations run by two employees for each joining technology.

Solution

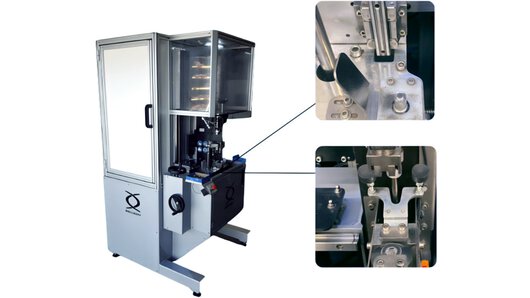

One machine combined for both applications

For this reason, Böllhoff offered to make Tôlerie Forézienne a customised machine that combined crimping and clinching.

RIVCLINCH® technology is a cold-forming method for metal joining. It offers an alternative to welding and makes deformation possible when needed.

RIVKLE® is a crimping method to join thin-walled components. The set-up is blind.

Result

Productivity gains

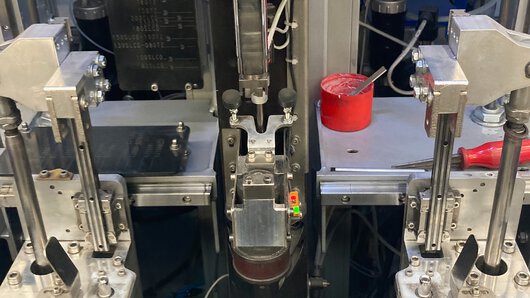

The RIVKLE® and RIVCLINCH® special machine crimps and clinches the part at different points at the same time, decreasing the time it takes to join the chimney flues. Tôlerie Forézienne was able to increase productivity by a whole assembly station and reassigning two employees to different positions. There are financial savings too as it reduces maintenance and decreases joining time.

Customer benefits

- Increased productivity

- Lower maintenance

- Financial savings

Gallery

we will be happy to help

Do you have any questions or a current project?

Just let us know and we’ll get in touch

Contact us