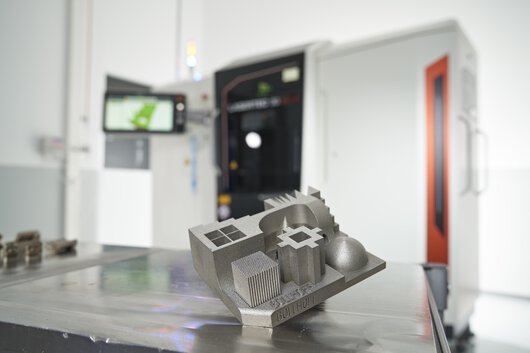

We analyse global market trends and set out clearly defined areas in which we systematically search for innovations. Example: In one of countless search fields, we looked for ideas on how we could use our production expertise to implement intelligent fasteners for aircraft seats. Promising ideas from our employees are then presented to the Innovation Steering Committee.

About Böllhoff

Innovations at Böllhoff

Innovations do not occur in isolation – you need good ideas, the right methods and a lived innovation culture.

A problem solver for joining technology

Innovation ensures our success

Innovation is vital to the success of our company. This is why it is firmly anchored in our corporate strategy. Every Böllhoff innovation has to solve a specific problem for our customers.

We see ourselves as “a problem solver for joining technology”: We supply every customer with the right fastening solution – regardless of the components they want to connect.

»"For us, innovation occurs when an invention matches a customer requirement – that is, when there is a market for a new product or a new process."

A culture of innovation

Innovation needs the right environment

All innovation management measures have a single goal: to promote a culture of innovation within our company. We encourage all employees to get actively involved because they are the true experts when it comes to market trends and the challenges faced by our customers, allowing them to tap hidden potential.

Trust is a crucial factor here. The best environment for innovative ideas is to trust your employees and “let them get on with it”. This means that some ideas will also fail, because not every good idea becomes a successful innovation. But it is important to enable a positive type of failure and to also see every unimplemented idea as a valuable contribution. Because every unimplemented idea is still a small step to the next innovation.

»"Courage and trust are two cornerstones of our corporate culture. You can only create a culture of innovation in a company by trusting your employees and by encouraging them to be brave and to think outside the box."

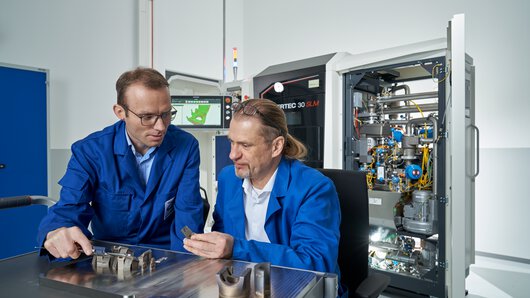

Innovation needs the right partnerships

New ideas also arise from exchanges based on partnership. That’s why we have increasingly opened up our innovation process to the outside world in recent years. We call this: Open Innovation.

In addition to existing partnerships with leading research institutes and universities, we have also participated in the METEOR project since 2021, for example. The joint project METEOR (methods and technologies for validating and optimising the resource efficiency) aims to reduce CO₂ emissions in the production of lightweight structures by up to 80 percent. We support this by investigating new methods for robot-assisted joining of plastic/metal composite structures. We are also part of the “It's OWL” technology network as a core partner when it comes to developing intelligent approaches for digital transformation.

»"We are proud to announce that we currently have around 1,000 patents and patent applications pending. And every year, around 15 to 25 new property rights are added in Europe."

Documentary about Böllhoff

Learn more about how we support our customers with 360° joining technology and drive forward innovations in the process – in this video from the “Innovation Deutschland” series.