Success stories

Europipe

Our largest HELICOIL® convinced Europipe in technical and economic terms

Extended life expectancy

An avoidable cost factor: fast wearing threads. With our biggest-ever HELICOIL® thread inserts we were able to extend the service life of the tools.

Initial situation

High degree of wear

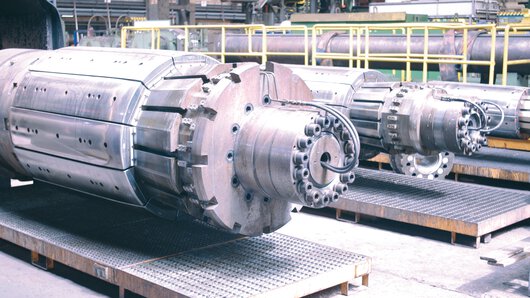

When manufacturing large pipes, the company uses a two-head expander in the final forming stage.

The welded pipes are gradually cold-enlarged using the expander to achieve the dimensional accuracy and the required geometrical data. The expansion rate differs depending on the pipe’s diameter, the thickness of its walls and the material used. It varies between 0.8 % and 1.5 %. The permanent strain of up to 1,500 tonnes of tensile load caused wear to the threads on the expander's tension rods. Due to the resulting costs, a long-lasting solution was needed.

Solution

HELICOIL® thread insert

Heavy loads call for strong solutions. We worked together with EUROPIPE to develop an tailor-made solution. This involves screwing a HELICOIL® thread insert into the tension rod nut to improve distribution of the pre-tensioning force during the mechanical expansion process. Increasing the thread’s fatigue strength significantly extends the service life of the mechanical expander.

- Fatigue strength without HELICOIL® 600 to 950 t

- Fatigue strength with HELICOIL® 750 to 1200 t

For EUROPIPE, we have produced our largest HELICOIL® thread inserts ever, measuring:

204 x 16 x 282 mm, 260 x 20 x 330 mm and 320 x 25 x 420 mm.

Result

Tool service life extended

We work closely with our customers to develop tailor-made solutions. This is just one example of that close collaboration.

With HELICOIL® inserts we created wear-resistant, high-precision threads. Increasing the strength of the threads made it possible to extend the service life of the expander tension rods.

Customer benefits

- Uniform load and stress distribution

- Thread reinforcement

- Quality improvement

we will be happy to help.

Do you have any questions or a current project?

Just let us know and we’ll get in touch

Contact us