Direct screw-fittings

EJOT EVO PT®

Innovative and reliable: The self-tapping screw for plastics with high mechanical security.

For maximum safety

Securely fasten plastics: Evolutionary advantages for permanent connections

The EVO PT® represents the next step in our systematic development of the self-tapping screw for thermoplastic materials. With this innovative fastening solution, for the first time EJOT has combined expertise in manufacturing and application technology with findings obtained from physical computer simulations. The result is a screw that sets entirely new standards for direct fastening of plastics.

Plus factors

Advantages EJOT EVO PT®

Increased effectiveness and efficiency

Considerable cost savings can be achieved by systematically avoiding costly bore tapping operations and inserts.

Secure setting

The newly developed thread tip of the EVO PT® enables easy and straight placement in the screw hole. The EJOT plastic screw centres itself in the screw hole for the screw-in process.

High connection quality

The special setting thread creates uniform load distribution over the circumference of the screwed-in thread flanks. Autonomous centring of the EVO PT® in the screw hole ensures high repeatability and extremely high connection quality.

Less variety of parts, more efficiency

In the screw-in phase, the innovative formed thread turn causes a torque curve that is virtually independent of the depth of thread engagement. This enables standardization of screw lengths and tightening torques, which in turn directly affects the efficiency of your process chain positive.

Digital service for optimized components

The digital calculation service EVO CALC® enables prior calculation of torques and preload forces as well as preload force relaxation under temperature and time. In addition, EJOT offers an individual, FEM-supported component analysis; this save you time and reduces costs.

Innovative properties

The self-tapping screw EVO PT®

With the EVO PT® nothing was left to chance. The entire design of this self-tapping screw has been re-engineered and focuses on the requirements of users, designers, lean managers and buyers.

The screw's consistent design emphasis on customer benefits is evident in the innovative technical properties of the EVO PT®.

Extensive service

We support you in the design

For the EJOT EVO PT® we offer an extensive service package that guarantees optimal use of the screw.

Our in-house specialists in Application Technology support you with expert technical advice. An extensive portfolio of technical test equipment and digital instruments is available to you for application validation.

Preconfigure your screw connection with EVO CALC®

The EVO CALC® forecasting program, developed especially for this screw, allows fast and precise determination of all important data for your project. Such data also include the information for installing the EVO PT® screw

In this regard, the program creates a design recommendation or a calculation of relevant torques. The program also determines the various forces, such as preload force at tightening torque, and shows possible types of failure at overload.

The results give you immediate indications as to whether your assembly is already optimally designed for your requirements or which aspects must be improved to achieve the desired result.

FEM analysis – planning reliability with numerical calculation

Analytical calculation methods ensure calculation of design and assembly parameters quickly and with sufficient accuracy. However, the question often arises as to how the preload force will behave in the load case after assembly. For a plastic direct fastening, particular attention must be paid to relaxation, i.e. time-dependent and temperature-dependent loss of preload force.

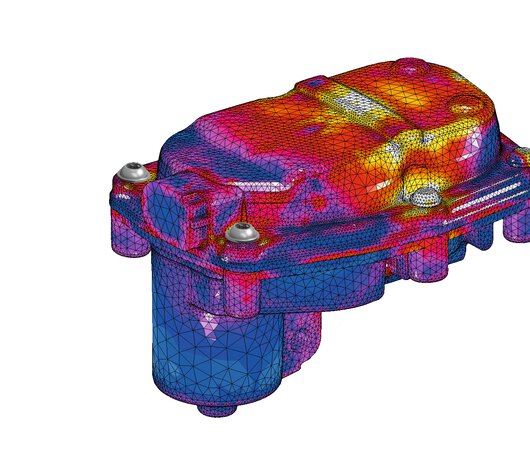

Analytical calculation models are not precise enough for reliable prediction of this process. This is why we equipped EVO CALC® with an interface to a numerically calculating FEM (finite element method) system. With this program you can define a load case by means of a simulating temperature profile. This load case, together with the relevant initial conditions and design parameters, is used for the numeric calculation.

By interacting with complex material models, the FEM system calculates the anticipated preload force curve and then the final residual preload force. Thus, time-intensive and cost-intensive temperature tests can be reduced to a minimum.

Information and more

Downloads

Are you interested in EJOT EVO PT® self-tapping screws? Please download further information here.