14/03/2024 | Company

High tech and automation in manufacturing

Since November 2023, parts transfer in our assembly production has been fully automated.

State-of-the-art technology in the service of people

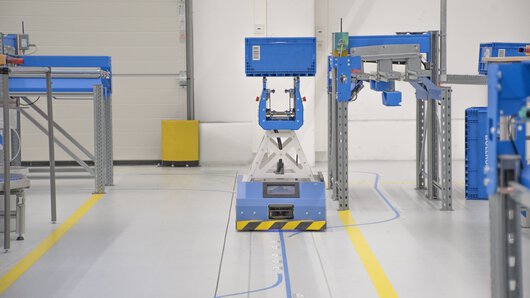

At Böllhoff, we are continuously advancing digitalisation and automation – always with a view to the benefits for our employees and customers. This is the case at the assembly production location in Bielefeld, where parts transfer has been fully automated since November 2023. Nine automated guided vehicles (AGVs) zip around delivering raw parts and transporting finished parts according to the needs of the manufacturing machines. Including automatic storage and retrieval of all parts in buffer storage systems.

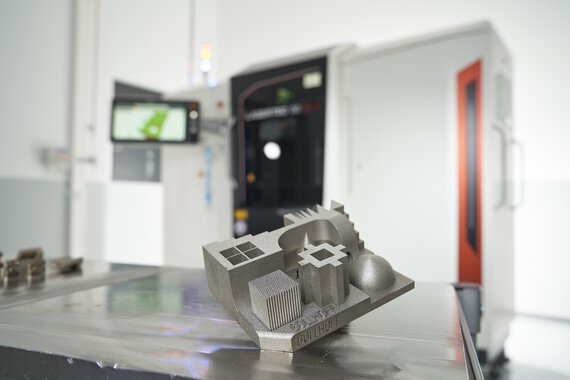

Special manufacturing, special fasteners

Every day, over 2 million plastic fasteners are created in our injection-moulding manufacturing at the Böllhoff headquarters in Bielefeld.

For some of the fasteners, the journey through the production facility goes even further: In the assembly production area, they are used as raw parts and assembled with other parts. This creates fasteners with special additional functionality, for example from the FLEXITOL® product family. These components can, for example, compensate for manufacturing tolerances in body parts or decouple vibrations.

To handle such a wide variety of components, the workers in assembly production have been working at 26 production machines alongside 9 AGV systems since November 2023.

»"During this automation project, we redesigned the routes taken by all parts to the production machines and back to the storage location. It’s a move away from manual processes and towards just-in-time delivery – with automatic storage systems and automated guided vehicles."

»"This is a big step into the digital future for us, and an important way of making work easier for our employees in logistics and production."

More efficient processes and greater added value instead of manual processes

Previously, logistics workers would deliver the necessary raw parts for the day to the machines early in the morning. They also picked up finished parts from manufacturing – a time-consuming process involving 26 production machines. Raw parts and finished parts also had to be stored temporarily on pallets directly by the machines. Not only did this take up valuable space, it also meant that workers in manufacturing had to spend additional time looking for the materials they need.

Thanks to automated parts transfer, such manual processes and obstacles are now a thing of the past.

From the storage bin to the machine and back: AGV makes it possible

Now, our logistics workers store all raw parts in an automatic buffer storage system in the morning. All the parts for the day are kept in containers in almost 1,000 storage bins. If a manufacturing worker needs new parts for a machine, they can simply request replenishment at the push of a button. The trick: The path of the container from the storage bin to the production machine is then completely automated – with no human intervention.

- All at the push of a button

- The resupply delivery begins

- An AGV prepares for deployment

- Supplies are on the way

- The delivery arrives

When a manufacturing worker needs new parts, they simply trigger the replenishment delivery at the push of a button on the production machine.

The buffer storage system then removes a container with the desired raw parts – completely automatically. At the same time, an automated guided vehicle system (AGV) is required to transport the parts to the machine.

Almost like a taxi rank: the AGVs wait for their next mission.

An AGV takes the replenishment parts directly to the respective production machine.

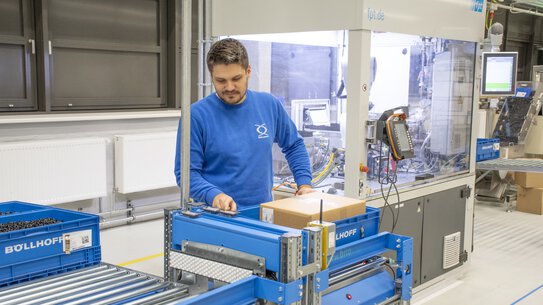

When it arrives at the machine, the AGV places the supplies at a transfer point. The manufacturing workers can now equip the respective machine for the next production batches.

The removal of finished parts from the production machines also follows the same logic. When a manufacturing worker has stowed all the parts in the appropriate container, they place it on a transfer point. They also initiate collection at the push of a button. An AGV collects the container as quickly as possible and transports it to a second buffer storage system. Almost 1,000 additional storage bins for finished parts are kept here, and the container is stored automatically in one of them.

»"Automating the transport routes in assembly production allows our colleagues to concentrate on activities where human skills are essential."

Hard-working robot helpers in constant use

The pilot phase of the project began in August 2023, when the new processes were tested on some production machines. The AGVs have been in continuous use for all 26 machines since November. Around 650 meters of driving lanes have been set up in the production halls.

“The colleagues were already very interested in the new robot helpers during the pilot phase”, says Head of Intralogistics André Koring. “Everyone wanted to be part of the change and kept asking us when their production machines would also be connected. It was a nice confirmation of our commitment to continuously reinventing ourselves as a company.”

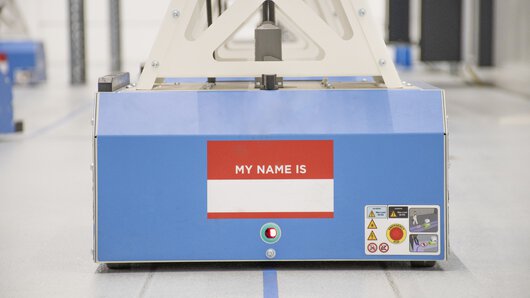

There’s just one thing the robot helpers are currently lacking in order to fully integrate into the team: the right names. That’s why all nine AGVs are set to be “baptised” in the near future to make the cooperation even more personal.

»"In 2021, I joined Böllhoff as a student trainee while continuing my mechanical engineering studies. That gave me the opportunity to be involved in this automation project right from the start – and I’m still involved in it today. It’s a great feeling to be actively involved in shaping the manufacturing of tomorrow!"