Joining lightweight materials efficiently

Flexible and reliable

WELTAC® resistance element welding enables you to join lightweight materials with steel of all qualities. A rivet-like element serves as an auxiliary joining part enabling different materials to be joined together. And the best thing about it is that you can use existing spot welding systems for modern car body construction for the second stage of the WELTAC® process.

Plus factors

Advantages of WELTAC®

Flexible combination of materials

Lightweight materials, such as aluminium, sandwich materials and polymeric materials, can be joined with steel of all qualities.

Use of existing equipment

You can use your existing resistance spot welding systems for modern car body construction for the second stage of the WELTAC® process.

High-strength joints

WELTAC® is an extremely flexible technology that consistently produces high-strength joints.

Proven system

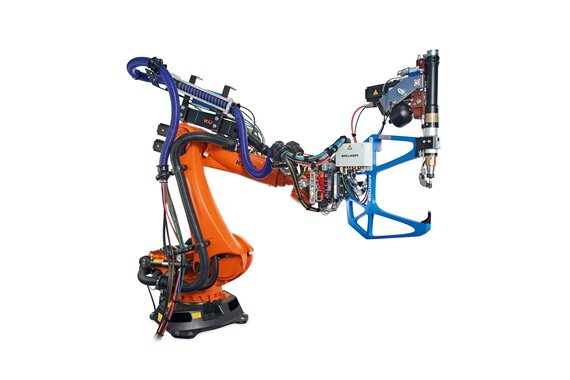

The first stage of the WELTAC® Automation process is based on the tried-and-tested processing systems RIVSET® Automation E and EH.

Method and principle

How does resistance element welding work?

In the first stage of the process, a rivet-like WELTAC® element, used as the auxiliary joining part and made of a material compatible with the base sheet, will be punched in to the upper material layer (e.g. aluminium). This component is then welded to the lower steel material layer(s) in the second stage of the process.

Böllhoff only supplies the WELTAC® elements and the WELTAC® Automation for the first stage of the process.

For the full variety of applications, we offer a selection of different welding elements in different lengths and head designs as well as for different mechanical loads.

We will be pleased to advise you on the right solution for you.

Information and more

Downloads

Interested in WELTAC®? Please download further information here.

Any questions?

We are here to assist you

Want to know more about our products or services? Our team will be happy to advise you.

Contact us