The mobility of the future with Böllhoff

We have been a development partner to many industries for decades when it comes to joining elements. We are also actively shaping the mobility of tomorrow in this way.

Electromobility - a pillar of tomorrow's mobility

What will mobility look like in the future? Whether in public or private transport, different ideas and drive concepts are currently being put to the test.

However, one thing is certain: the central goal for the mobility of tomorrow is to reduce the emissions generated in the transport sector. Electromobility is one of many levers here.

Focus on applications

Where we are represented in e-mobility today

From electric cars to e-bikes: our joining solutions can be found in many electrically powered means of transportation - and in a wide variety of applications. For example, we make lightweight construction possible and create resilient and media-tight connections. Here you can gain an insight into selected applications in the field of electromobility.

- Load-bearing threads for lightweight construction

- Tight joints in the battery tray

- High-strength joints for the charging infrastructure

- Decoupling vibrations and noise

- Battery compartment cover for e-bikes

Consistent lightweight construction remains a focus topic in the automotive industry, including for e-mobility. This is because vehicle weight has a direct impact on energy/fuel consumption and range. Our thread inserts such as the HELICOIL® Smart create resilient threads in lightweight components such as aluminium. Due to the low shear strength of the light metal, threads would simply tear out without this reinforcement.

Find out more about HELICOIL®

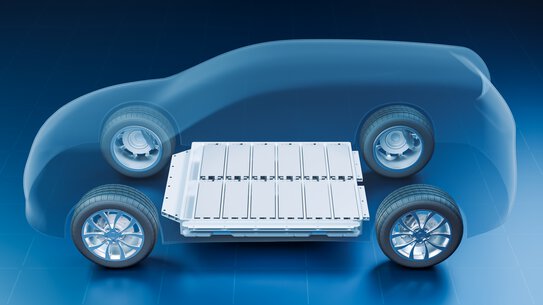

The heart of every electric car is the high-voltage battery. The battery tray must be securely fastened - with two challenges: Material thicknesses of 3-4 mm at the screw-on points do not allow for a cut thread. In addition, all joints must be 100% media-tight. A case for RIVKLE® Seal Ring blind rivet nuts: they create load-bearing threads in thin components and seal at the same time.

Find out more about RIVKLE®

Electric cars also need to "refuel". In the charging infrastructure for electric cars, Böllhoff expertise also ensures sustainable joinings - whether in the charging station or in the charging plug. Take charging plugs, for example: as these are usually made of plastic, our AMTEC® thread inserts come into play. They create high-strength metal threads in lightweight plastic components.

Learn more about AMTEC®

The quieter a vehicle is in general, the more likely it is that unwanted background noises can be heard in the interior - for example due to moving components. Vibration decoupling is therefore also relevant in electric cars. After all, there is hardly any engine noise that could mask any background noise. This is where our SITEC® elements come into play: they reduce vibrations and therefore noise to a minimum.

Find out more about SITEC®

Even an e-bike can't do without a battery. In terms of longevity, the battery should be easily accessible and replaceable - and at the same time protected from dust and the elements. With frame-integrated battery compartments, this is achieved with a removable cover. Often installed inside: QUICKLOC® quick-release fasteners. They allow the compartment to be opened and closed literally in the blink of an eye.

Find out more about QUICKLOC®»"Developing innovative joining solutions and helping to shape the mobility of the future - that is our mission at Böllhoff. We are proud that our products can already be found in many applications today. And often invisible to the eye, as 'hidden champions' behind the scenes."

Want more insights?

360° joining technology for electromobility in the video

We have the secure joints for new propulsion systems. Discover numerous applications specifically for electric cars in our video.